As Sibo's star potentiometer product,WDD35D4 has been widely acclaimed since since its launch,ith impressive performances across various industries including military, aviation, automotive, medical, measurement, robotics, and so on. Today, we will unveil the "past and present" of the WDD35D4 product and let everyone see what this product is truly worth.

The "Past and Present" of Conductive Plastic Potentiometers

Conductive plastic potentiometers emerged in the mid-to-late 1950s, initially developed by New England Instruments in the United States. In 1959, the United States patented the conductive plastic potentiometer. In the 1960s, after a U.S. U2 reconnaissance plane was shot down, conductive plastic potentiometers were discovered. However, it remained highly confidential in the United States until around 1970 and was listed as a prohibited item by the Coordinating Committee for Multilateral Export Controls.

To develop domestically produced long-life, high-precision potentiometers, China began researching this topic in the 1960s, with research led by a certain aerospace institute. By the early 1980s, production technology for potentiometers from a Japanese brand was introduced, marking a breakthrough in conductive plastic potentiometer technology and the beginning of its localization process.

The Basic Principle of Conductive Plastic Potentiometers

Newcomers might be puzzled by the term "conductive plastic" – how can "plastic" be "conductive"?

The resistive element of a conductive plastic potentiometer is made by mixing plastic material (used as a binder) with conductive material.The plastic binder is typically thermoset,such as epoxy, phenol and alkyd, etc., while the conductive material is silver or other metal powders, carbon black, graphite, etc. This mixture is known as resistive paste.The resistive paste is coated onto the surface of a thermosetting material, then molded into different shapes through high-temperature molding to form the resistor body.

Apart from the paste, the brush of the potentiometer is also a key factor affecting its performance. We use a six-element brush and current collector wire containing palladium, platinum, cobalt, and other precious metals to ensure stable and reliable potentiometer performance.

When the brush slides on the substrate, it acts as a voltage divider on the substrate. Since the voltage at both ends of the substrate is stable, the voltage between the brush and the output varies with the angle as the brush slides across the substrate. This voltage change is proportional to the mechanical displacement, allowing indirect measurement of the mechanical displacement by measuring the voltage.

The Structure of Conductive Plastic Potentiometers

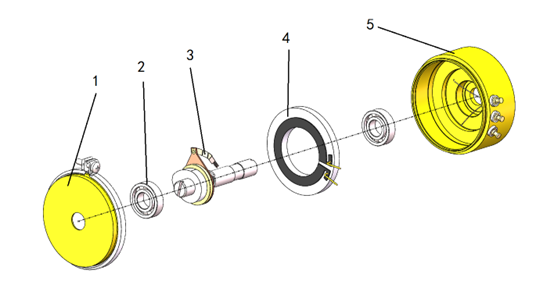

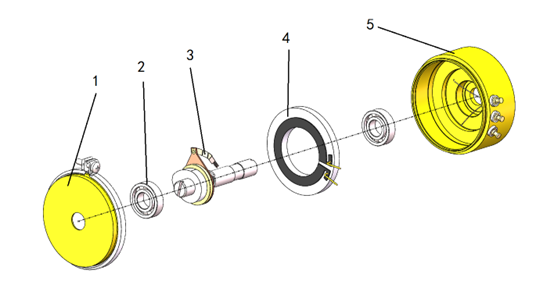

Taking Sibo's WDD35D4 as an example, let's introduce the structure of conductive plastic potentiometers.

Substrate (part 4 in the picture): This is the core part of the potentiometer , made of conductive plastic material.

Brushes (part 3 in the picture): Brushes are the movable parts in the potentiometer, which are mounted on the shaft of the potentiometer and are driven by the rotation of the shaft to slide on the surface of the substrate, thus changing the resistance value.

Bearings (part 2 in the picture): Usually used in pairs, they support and position the potentiometer shaft on which the brushes are mounted to ensure its smooth movement.

Housing (part 5 in the picture) and Back Cover (part 1 in the picture): Typically made of rigid aluminium alloy to protect the internal components from external interference and damage.

The Advantages of Sibo's Conductive Plastic Potentiometers

High Precision: The WDD35D4 conductive plastic potentiometer features high precision, accurately converting mechanical displacement into electrical signals.

Long Lifespan: Using thermosetting plastic particles hot pressing moulding, as the resistive substrate, with conductive plastic paste as the resistive material. most manufacturers use materials from Japanese companies for the substrate, the brush have a wider selection, often from German companies. Conductive plastic potentiometer generally have a long lifespan, with wear depending on wiper pressure. Their lifespan and reliability are inversely proportional, ranging from 10 million to 100 million cycles.

Good Stability: The design and manufacturing process of the potentiometers is strictly controlled to ensure stable performance under different environmental conditions.

High Customizability: According to customer's demand, we can provide many kinds of special specifications and customised services, such as special resistance value, centre tap, Multi-ganged, with pointer, with stop, etc.

Looking Ahead: Sibo is Ready to Partner with You

The development of potentiometers has never stopped.The emergence of conductive plastic potentiometers has improved the lifespan and stability of potentiometers; the development of printing technology significantly reduced production costs.Today, with the development of electronic technology, SENTOP digital potentiometers (Hall sensors) have gradually become the focus of the market. There is not only analogue signals, but also serial signals, bus signals and so on. The lifespan is more practical up to hundreds of millions of times.

A Full Range of SENTOP Digital Potentiometer (Hall Sensor) Products

From conductive plastics to digital technology, each stage has driven the progress of potentiometer technology. Today, fully domestically produced SENTOP digital potentiometers (Hall sensors) not only technologically advanced to meet the needs of domestic customers, but are also constantly exported overseas, becoming the pride of the potentiometer industry!

Welcome to use WeChat to scan the QR code, add exclusive customer service for Sibo, and obtain more information.

More information

Shanghai Sibo M&E Co., Ltd is a renowned enterprise and recognized by numerous awards such as Shanghai High-tech Enterprise, Shanghai "Specialized and Innovative" Enterprise, Shanghai SMS Enterprise, Shanghai Class AAA Contract Credit Enterprise, Class A Taxpayer Enterprise, and Shanghai Advanced Private Enterprise. Meanwhile SIBO has achieved quality management certification ISO9000.The company's products have been exported to overseas markets such as Southeast Asia, Europe and the United States for a long time. There are thousands of types of products, including potentiometers, joysticks, pedals, draw wire sensors, encoders, handwheels, and signal communication modules. Welcome to inquire and patronize!

For more product information, please visit Sibo's website at www.sakae.cn/es/